Carbon Footprint Analysis of a Mass-Market Body Lotion

The Opportunity

Personal care brands are under increasing pressure to reduce product carbon footprints — but many struggle to identify where emissions actually come from and which changes matter most.

This case study demonstrates how a screening-level lifecycle analysis can uncover high-impact, cost-neutral reduction opportunities in a mass-market body lotion sold at multi-million-unit scale.

What We Analyzed

Product:

32 oz (≈0.95 kg) hand & body lotion

High-volume, globally sourced ingredients

Scope included:

Ingredient production

Primary packaging

Upstream transportation of raw materials

Scope excluded:

Consumer use

End-of-life

Corporate overhead

The goal was speed, insight, and decision relevance — not perfect precision.

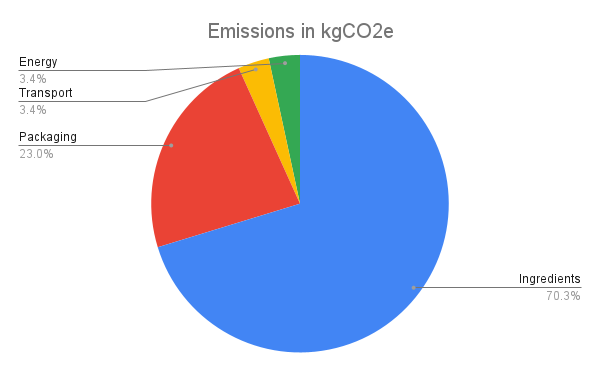

Where the Carbon Footprint Really Comes From

Most emissions are baked into the formulation and packaging, not shipping distance.

Emissions Breakdown:

Ingredients: ~0.95 kg CO₂e

Packaging: ~0.35 kg CO₂e

Raw material transport: ~0.05 kg CO₂e

Manufacturing energy: ~0.05 kg CO₂e

Headline takeaway:

Ingredients alone account for over 60% of total product emissions.

This immediately tells brands where to focus.

Ingredient Insights (Anonymized)

To protect product confidentiality, ingredients are grouped into functional categories:

Purified water

Bulk plant oils (primary & secondary emollients)

Lightweight esters

Fatty alcohol / emulsifier system

Botanical extracts

Essential oil fragrance

Vitamins, preservatives, stabilizers

What surprises most teams

Some botanical extracts and essential oils show very high kg CO₂e per kg, but they contribute little to the total footprint because they’re used at low levels.

The real drivers are bulk oils and structuring agents.

Transportation: Important — but Not the Main Lever

Despite global sourcing:

Most ingredients ship by ocean freight

Water is assumed to be sourced locally

No air freight assumed

Result

~0.05 kg CO₂e per bottle

≈ 3–4% of total footprint

This confirms a common LCA insight: what ingredients are made from matters more than how far they travel.

Reformulation Scenario: Real Reductions, No Trade-Offs

We modeled a practical reformulation strategy that preserves performance, claims, and consumer price.

Changes tested

~10% reduction in total oil phase

Partial substitution of the highest-impact bulk oil

~15% reduction in fatty alcohol / emulsifier loading

No changes to botanicals, fragrance, or actives

No premium materials. No offsets. No greenwashing.

Ingredient Footprint — Before & After

Results:

Baseline ingredients: ~0.95 kg CO₂e

Optimized formulation: ~0.81 kg CO₂e

~15% reduction in ingredient-related emissions per bottle

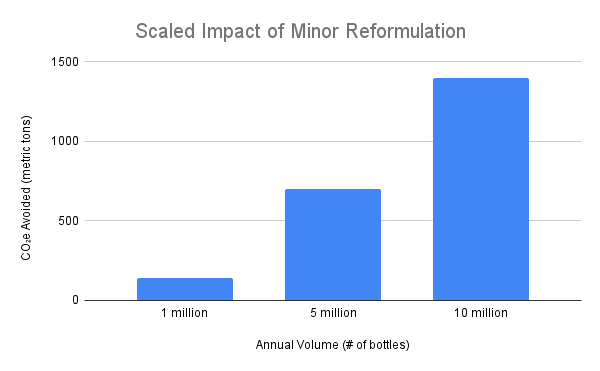

Why This Matters at Scale

For a product shipped in millions of units per year:

Annual Volume ~ CO₂e Avoided

1 million bottles ~ 140 metric tons

5 million bottles ~ 700 metric tons

10 million bottles ~ 1,400 metric tons

Small formulation changes become material climate wins at scale.

What This Case Study Demonstrates

✔ Carbon hotspots can be identified quickly

✔ Ingredient mass matters more than ingredient mystique

✔ Transportation is rarely the primary lever

✔ Double-digit reductions can be cost-neutral

✔ Sustainability and product performance don’t have to compete

Why This Approach Works for Brands

This type of analysis helps teams:

Focus R&D resources where they matter most

Avoid chasing marginal gains

Communicate credible sustainability progress

Make defensible, data-backed decisions early

How We Help

Each product is unique and requires its own analysis. We apply a similar methodology as this case study to:

Analyze your product’s ingredients, formulation and packaging

Compare footprints across alternative ingredients, formulations and packaging

Devise a path of maximum impact and minimum disruption

From screening studies to portfolio-level roadmaps, we help brands move from carbon curiosity to carbon action.