Reformulation vs. Recycled Packaging: How to Make Maximum Impact?

Product Type

Mass-market hand & body lotion (32 oz / ~0.95 kg)

High-volume consumer product sold at multi-million-unit scale

The Question Brands Are Asking

When brands commit to reducing product carbon footprints, the first question is often:

“Should we focus on reformulating the product — or switch to recycled packaging?”

This case study compares the carbon reduction potential of both strategies, using a representative personal care product as an example.

Scope & Methodology

This was a screening-level carbon footprint analysis, intended to support early decision-making rather than regulatory reporting.

Included

Ingredient production

Primary packaging

Upstream transportation of raw materials

Manufacturing energy (estimated)

Excluded

Consumer use

End-of-life

Corporate overhead

Functional Unit

One 32 oz bottle of lotion

All figures are approximate and based on publicly available emission factors and representative formulation assumptions.

Baseline Carbon Footprint

Per Bottle Emissions (screening)

Contributor ~kg CO₂e

Ingredient production ~0.95

Packaging (virgin plastic) ~0.35

Raw material transport ~0.05

Manufacturing energy ~0.05

Total ~1.35 kg CO₂e

Key Insight

Ingredient production accounts for over 60% of total product emissions, with packaging as the second-largest contributor.

Transportation plays a relatively minor role.

Strategy A: Ingredient Reformulation

What was Changed

A representative reformulation was modeled with no change to product performance, claims, or positioning:

~10% reduction in total oil phase

Partial substitution of the highest-impact bulk oil

~15% reduction in fatty alcohol / emulsifier loading

No changes to botanicals, fragrance, or actives

This approach focused on formulation efficiency, not premium substitutions.

Carbon impact: Reformulation

Baseline ingredients ~0.95 kg CO₂e

Optimized ingredients ~0.81 kg CO₂e

Reduction ~0.14 kg CO₂e per bottle

Result:

~15% reduction in ingredient-related emissions

~10–11% reduction at total product level

Strategy B: Recycled-Content Packaging

What was Changed

Replacement of virgin plastic bottle with high PCR (50–100%) HDPE or PET

No change to bottle weight or format

Packaging Emission Factors (typical)

Virgin plastic: ~2.5 kg CO₂e/kg

PCR plastic: ~1.2–1.6 kg CO₂e/kg

Carbon Impact: PCR Packaging

Baseline packaging ~0.35 kg CO₂e

PCR packaging ~0.20–0.25 kg CO₂e

Reduction ~0.10–0.15 kg CO₂e per bottle

Result:

~7–11% reduction at total product level

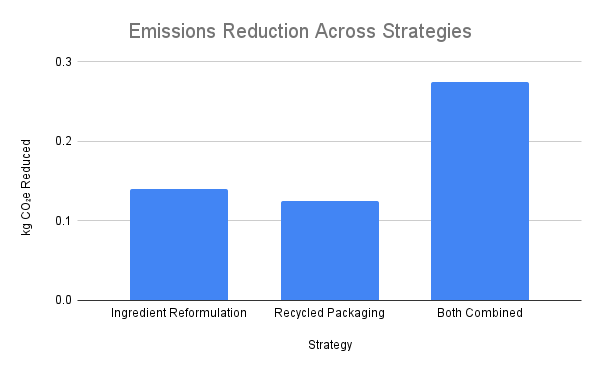

Side-by-Side Comparison

Per Bottle Reductions

Strategy kg CO₂e reduced % of total

Ingredient reformulation ~0.14 ~10–11%

Recycled packaging ~0.10–0.15 ~7–11%

Both combined ~0.25–0.30 ~18–22%

What This Means for Brands

Key Takeaway

Reformulation and recycled packaging offer comparable carbon reductions — but through different levers.

Reformulation targets embedded emissions

PCR packaging reduces material carbon intensity

Together, they compound into meaningful reductions

Cost & Implementation Considerations

Factor Reformulation PCR Packaging

Consumer price impact Neutral Neutral to slight increase

Time to implement Medium Short

Brand risk Low Very low

Consumer-visible No Yes

Long-term reduction potential High Moderate

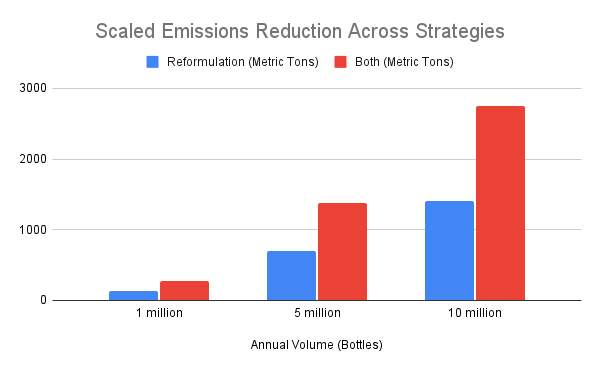

Impact at Scale

For a product sold at scale:

Annual volume CO₂e avoided (combined)

1 million bottles ~250–300 metric tons

5 million bottles ~1,250–1,500 metric tons

10 million bottles ~2,500–3,000 metric tons

Small per-unit decisions become material climate outcomes.

Why This Case Study Matters

This comparison demonstrates how lifecycle analysis helps brands:

Avoid over-focusing on single “silver bullet” solutions

Prioritize actions by impact, cost, and feasibility

Identify no-regret strategies early in product design

Communicate credible, data-backed sustainability progress

Our Approach

Each product is unique and requires its own analysis. We use screening LCAs like this to help brands:

Identify carbon hotspots quickly

Compare alternative strategies side by side

Focus resources where they deliver the greatest return

Whether the goal is reformulation, packaging optimization, or portfolio-level planning, the same principles apply.